Prototyping

In the fast-paced world of technology, prototyping and hardware development are essential steps in bringing innovative solutions to life. However, when it comes to antenna design, the challenges multiply. Designing an antenna that not only meets performance specifications but also fits seamlessly into the constraints of modern devices—whether due to size, power efficiency, or environmental factors—requires expertise and precision.

We provide end-to-end support, from initial concept and design to prototyping and final implementation. Our expertise ensures that your product not only meets the demands of today’s market but is also ready to scale as technology evolves.

Prototyping: Turning Concepts into Reality

After the design has been simulated and optimized, the next crucial step is creating a physical prototype. This is where the abstract design transitions into a tangible product, allowing for real-world testing and validation.

Material Selection & Fabrication Techniques

The choice of materials is essential in antenna prototyping, as it directly impacts performance, durability, and cost. Different materials may affect signal propagation, power efficiency, and environmental resilience. Quarterwave works closely with clients to select the most appropriate materials based on the application’s requirements, whether that means lightweight metals, composites, or advanced ceramics for high-frequency antennas.

Once materials are chosen, we employ cutting-edge fabrication techniques such as precision CNC machining, 3D printing, or photolithography. These methods enable us to quickly produce prototypes that are both highly accurate and representative of the final product.

Rapid Prototyping & Iterative Development

Speed is often critical in hardware development. At Quarterwave, we emphasize rapid prototyping, allowing us to quickly produce multiple iterations of the design for testing. With each iteration, we refine the design based on real-world performance data, whether it’s improving the antenna’s radiation pattern, reducing interference, or enhancing durability.

Our iterative approach ensures that we can make necessary adjustments before moving to the next stage of development, saving time and resources compared to traditional development cycles. Each prototype undergoes rigorous in-house testing to ensure it meets the desired specifications.

Functional Testing & Environmental Validation

Prototypes must be tested not only for functionality but also for their ability to withstand real-world conditions. Antennas may be exposed to a variety of environmental factors such as temperature extremes, humidity, and electromagnetic interference. Our testing protocols simulate these conditions to ensure the antenna performs reliably in the field.

Quarterwave conducts detailed analysis on factors such as signal strength, bandwidth efficiency, and durability. We also assess the antenna's performance under varying conditions to ensure it can meet the demands of your specific application.

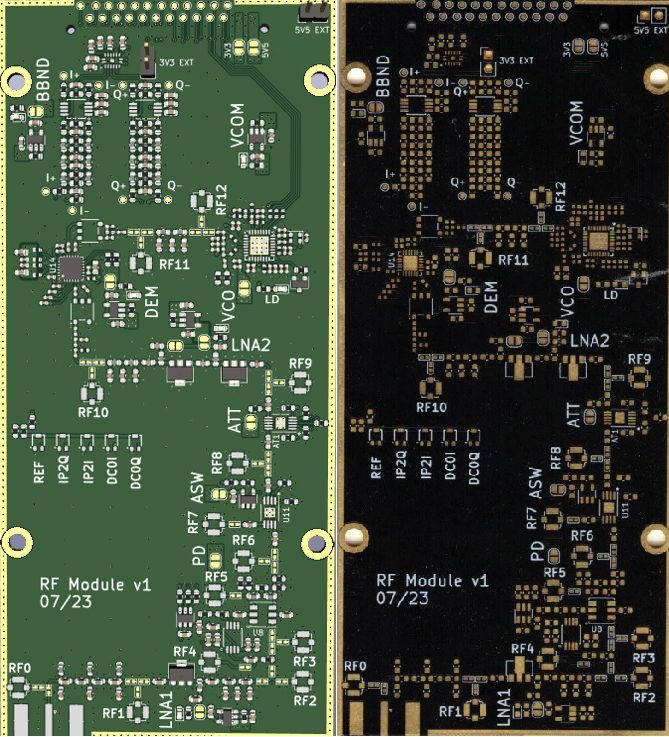

Receiver Frontend for digital wireless microphone system

Quarterwave is able to design and manufacture printed circuit boards of simple and medium complexity. The example shows a receiver module for a digital wireless microphone system, which was manufactured in a multi-layer process (6-layer).

A digital wireless microphone system is a technology that employs digital signals to transmit audio wirelessly from a microphone to a receiver. This type of system offers advantages over traditional analog wireless microphone systems in terms of audio quality, signal stability, and interference resistance.

© 2024 Designed by Quarterwave. All rights reserved.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.